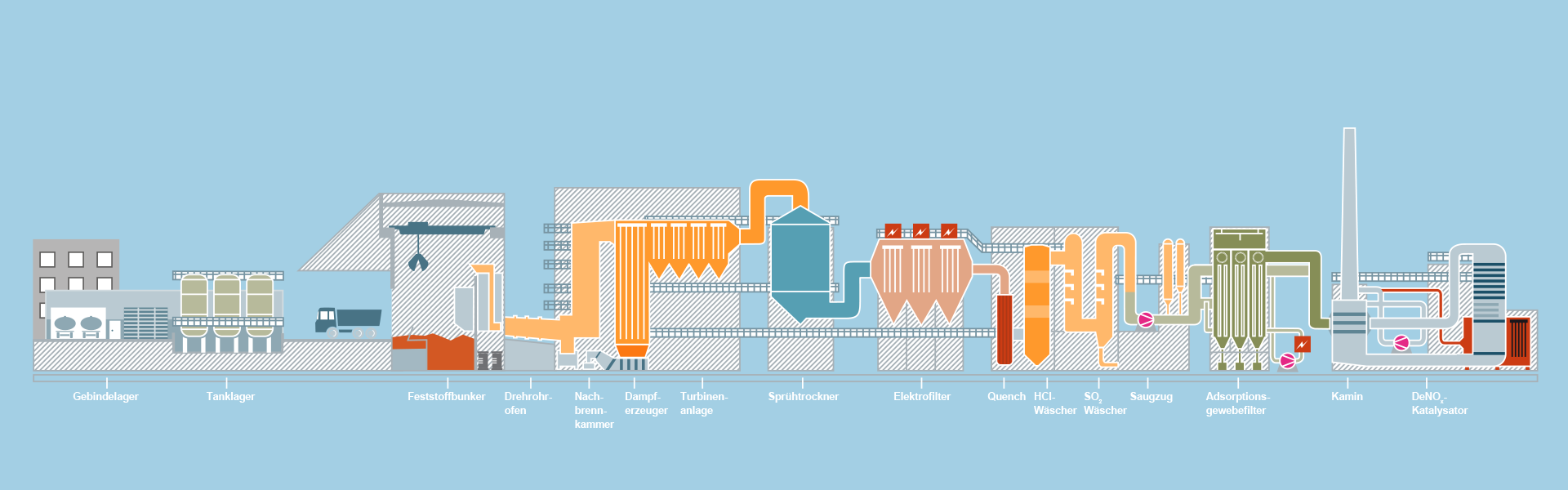

Plant laboratory

Before the vehicles are unloaded, the waste is inspected and samples taken and analysed in

the company’s laboratory in accordance with waste legislation.

Drum storage area

The high-bay warehouse is designed to hold 288 pallets of waste stored in small containers

and drums.

Tank farm

Liquid waste is pumped into the tank farm which has a total capacity of 720m³.

Bunker for solid waste

Solid waste delivered in containers and skips is tipped straight into the 700m³ bunker where

it is premixed before being incinerated.

Shredder and feeder

Closed drums are cut up in the shredder before being transferred straight to the rotary kiln

via the feeder.

Drum elevator

Chemicals, pesticides, herbicides and other types of harmful waste are fed straight into the

rotary kiln via the drum elevator.

Rotary kiln

The waste undergoes thermal treatment in the rotary kiln – the heart of the plant – to make

it non-toxic. The rotary kiln is fed specific mixtures of solid, liquid and pasty waste to

ensure the combustion properties vary only very slightly. During the thermal treatment, the

waste is slowly rotated towards the end of the kiln.

Wet slag extractor

The resulting slag drops into a water pool where it is cooled down and any metal contents

removed using a magnet. The recovered scrap is then sent for materials recycling.

Secondary combustion chamber

The secondary combustion chamber ensures all gases are fully burnt out, i.e. any remaining

organic substances are completely destroyed. In accordance with the 17th Ordinance of the

Federal Emissions Control Act, the dwell time of the gases must be at least two seconds and the

temperature a minimum 1,100°C.

Steam generator

The steam boiler generates steam (320°C / 40 bar) which is then fed into the turbine

unit.

Turbine

The steam is transferred from the boiler to the turbine where it is transformed into

electricity. Maximum output is 4.5 MW. Approx. 2 MW of this is used by the plant

itself and the rest is fed into the national grid.

Spray dryer

Following the generation of the steam in the boiler, the flue gas is cooled down in the

spray dryer by evaporating the neutralised wastewater from the quench and HCI scrubber.

Electrostatic precipitator

The dusty flue gases, which have been cooled down to 210°C, slowly flow through the

electrostatic precipitator. The fine dust is collected as a result of the ionisation process of

the dust particles.

Quench cooler

The quench cools the flue gases down to saturation temperature to protect the subsequent wet

scrubbing systems. The cooling process is carried out very quickly to prevent dioxins and furans

from forming. The quench is also used to extract mercury.

HCI scrubber

The HCI scrubber uses a two-phase process to remove hydrogen halides and any remaining dust

and heavy metals. The resulting wastewater is neutralised and then evaporated in the spray

dryer.

SO2 scrubber

The alkaline scrubber (lime milk) also operates in two stages and eliminates SOX

(sulphur oxides).

Gypsum dewatering system

A gypsum suspension is formed as a result of the oxidation process with atmospheric oxygen.

The water is removed from this mixture to create dry gypsum, which is sent on for recycling.

Suction fans

The fans transport the flue gas to the chimney generating a negative pressure – along the

entire system from the rotary kiln to the chimney – to ensure that the flue gas is unable to

leak out.

Adsorption fabric filter

The gases are heated up again so that they can be cleaned with activated carbon in the

adsorption fabric filter. After this, a mixture of fine lime and activated carbon is injected

into the system to re-move any organic trace elements and residual heavy metals from the flue

gas.

Gas-gas heat exchanger

The gas-gas heat exchanger heats up the flue gas for the catalytic converter and then cools

it down again before it enters the chimney.

DeNOX catalytic converter

The DeNOX catalytic converter transforms the nitrogen oxides into nitrogen and

water through the addition of an ammonia solution.

Chimney

The chimney releases the hot flue gas (approx. 140°C) into the atmosphere at a height of

60m. The gases are monitored and measured continuously.